Designing for robustness from day one

Senior Solutions Manager Kazuyuki Yamamoto explores how Secondmind helps engineers navigate high-dimensional NVH trade-offs when brute-force simulation is impractical

Automotive engineers must constantly push the envelope of design, often with new or unfamiliar architectures like the three-cylinder engine. A persistent challenge is ensuring vibration isolation (NVH) meets strict customer comfort targets while the car is stationary (e.g., at a traffic light).

This problem is exacerbated for a new engine type where the team has little direct experience, turning a high-dimensional, interconnected design problem - like optimizing multiple engine mount stiffnesses and positions - into a complex headache. The risk is high: choose a nominal design that fails later in development, and you face costly, time-consuming rework.

But the biggest hurdle? Robustness. We know that in mass production, engine mount stiffness will inevitably vary - up to ±10% is common. The conventional, tedious simulation-heavy approach requires checking every variation after selecting a nominal design, making it an inefficient process that often results in a non-robust final product.

From fragile to robust design

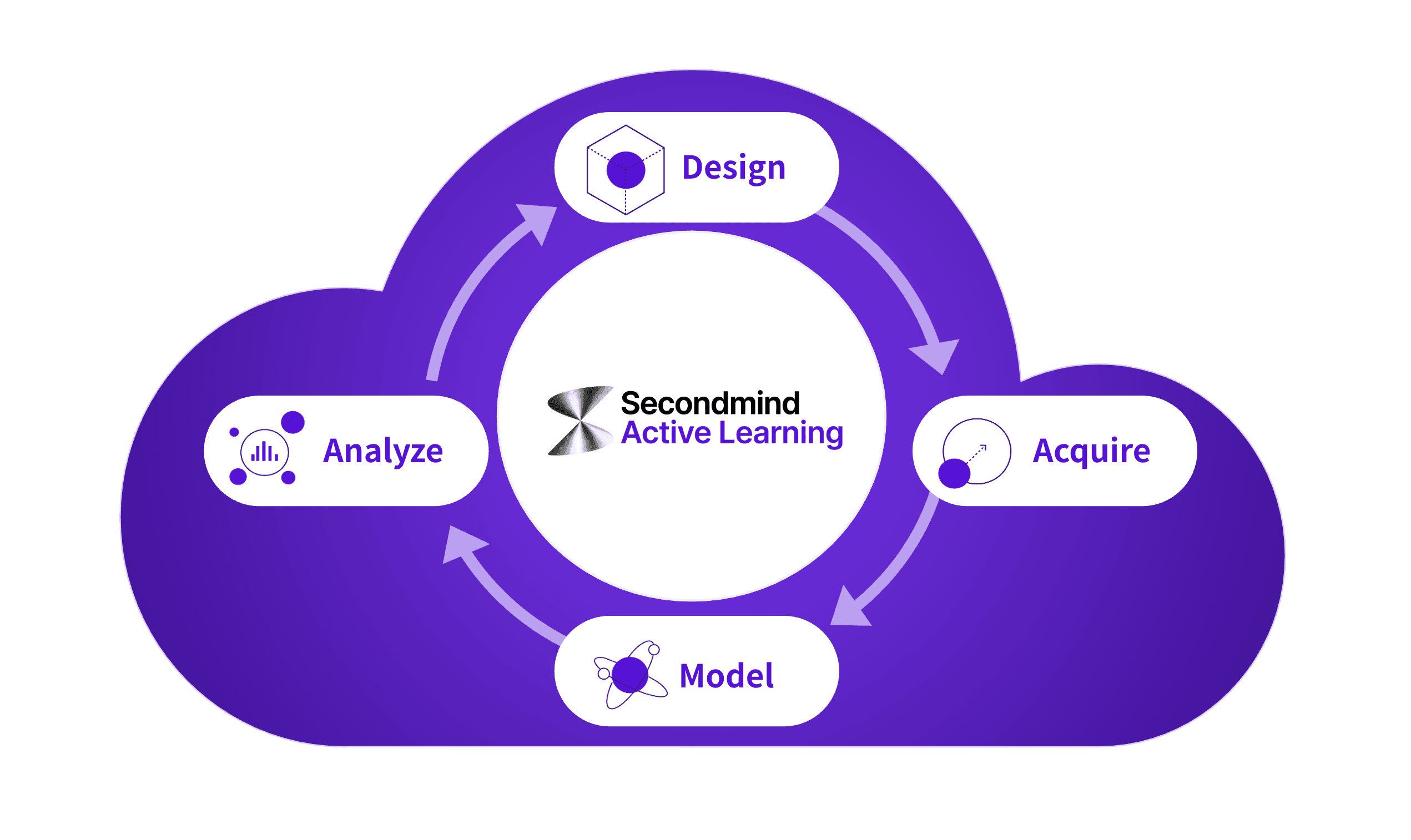

The goal of our software is to move away from risky point-based design and instead identify pre-validated design regions that inherently account for this ±10% stiffness variation. Secondmind for Design Space Exploration, powered by Secondmind Active Learning, has been developed to uncover large regions of high-dimensional feasible design space that meet the engineer’s set of requirements.

Data-efficient Secondmind Active Learning intelligently automates experimental design, rapidly reducing the amount of simulations required.

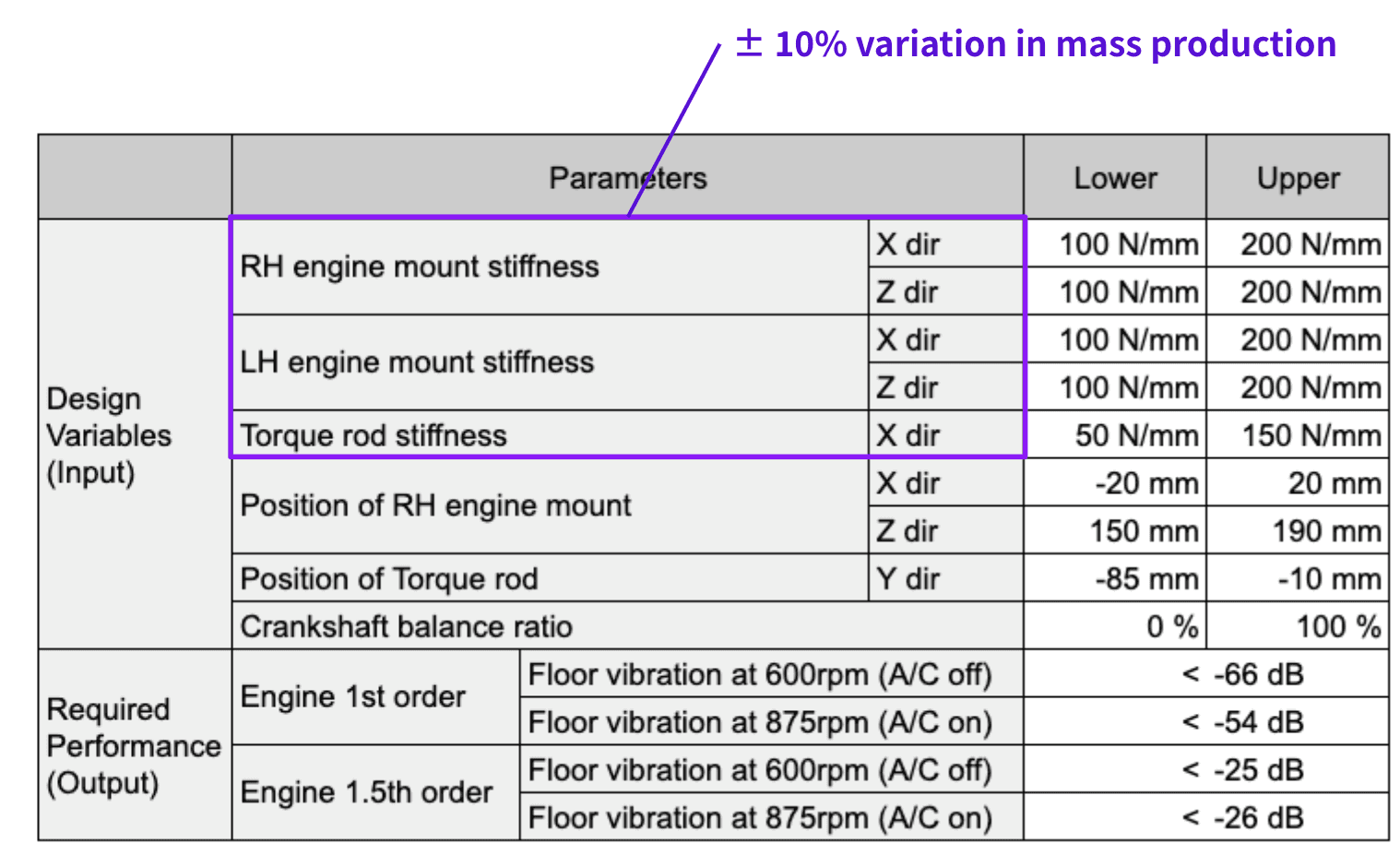

The design variables we optimized included nine distinct parameters: multiple engine mount stiffnesses in the X and Z directions, torque rod stiffness, and various mounting positions, alongside the crankshaft balance ratio. The requirements for performance (output) were focused on keeping floor vibration below specific decibel targets for the engine's 1st order (inertia force/pitch and yaw moment) and 1.5th order (combustion force/rolling moment) at both 600 rpm (A/C off) and 875 rpm (A/C on).

With nine variables to adjust simultaneously to hit the optimal trade-off across four stringent performance requirements, an engineer can easily wander endlessly through a sea of trial-and-error.We used Secondmind for Design Space Exploration to break this cycle by automating the search. While traditional iterative methods could mean that countless hours are lost to manual exploration, a mere two hours of intelligent, automated data acquisition was all Secondmind needed to gather the necessary information. Instead of the "brute force" approach of running tens of thousands of simulations - which can require over 78,000 iterations to map a high-dimensional space - Secondmind visualized the design space and obtained a robust solution using only 0.5% (400 vs. 78,125) of the conventional calculation workload.

Problem definition: idle vibration for 3 cylinder engine

New insights: the power of augmented intelligence

Achieving robustness from day one

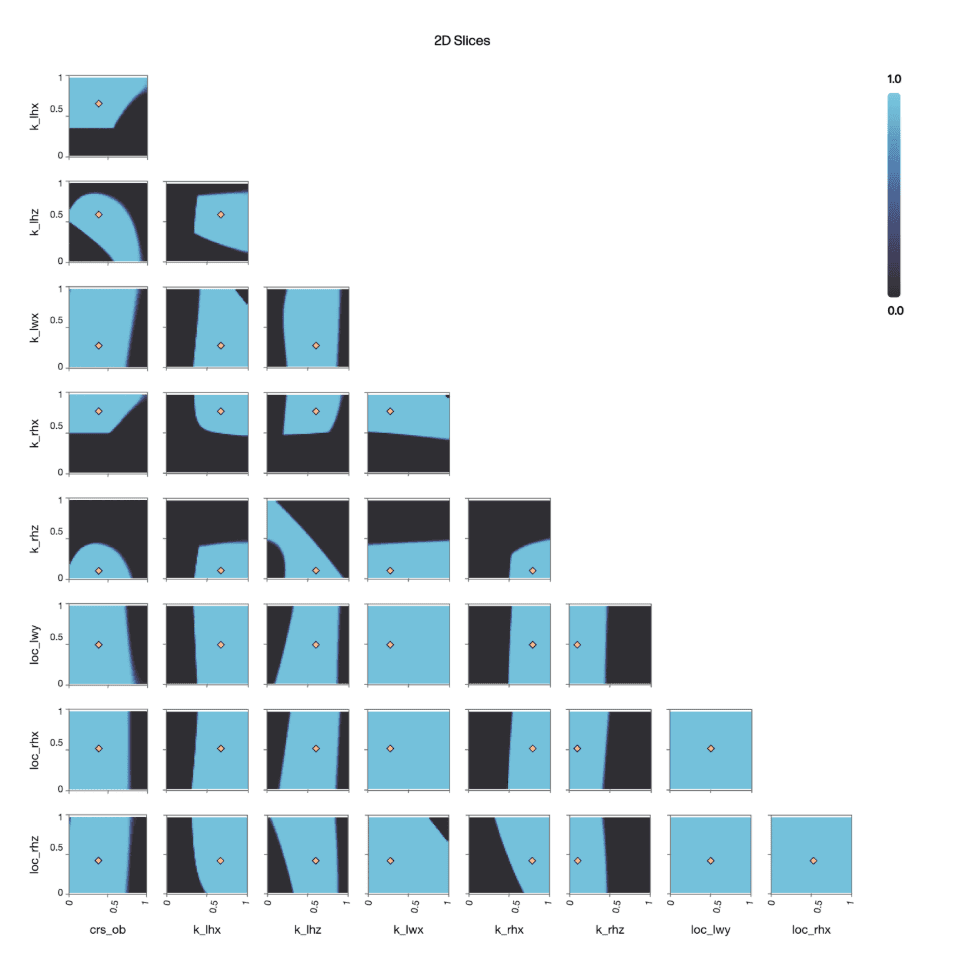

The true power of this approach wasn't just in speed and finding an optimal, robust design point; it was in the augmented intelligence gained from the Secondmind interactive user interface. Rather than looking at a single design point in isolation, the engineer can use Secondmind to explore the entire high-dimensional space through intuitive visualizations.

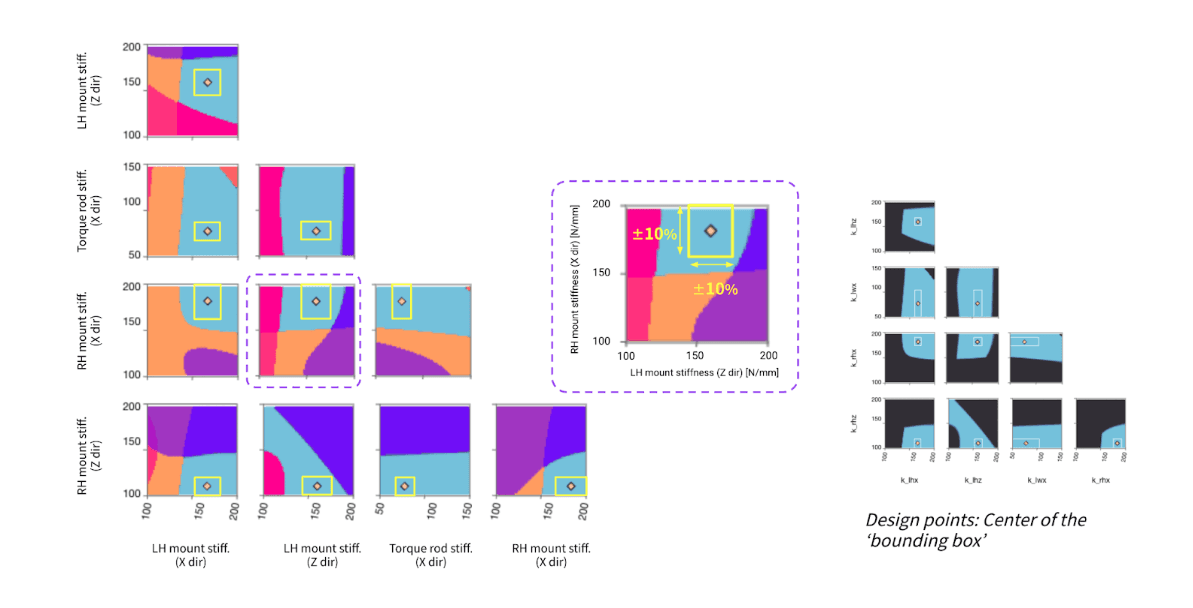

Secondmind’s 2D slice plots visualize the high-dimensional design space, clearly separating feasible designs (in blue) from the 'infeasible' regions that fail to meet vibration targets (in black). The central diamond identifies a robust design point that maintains compliance even when subjected to manufacturing variations.

A critical feature here is Design Sandbox. In mass production, you aren't just building one nominal design; you are building thousands that will inevitably vary. Secondmind allows you to identify a design point and visualize the largest variation box around it that remains within the feasible region. In this study, this box was confirmed to account for the inevitable ±10% manufacturing variations in engine mount stiffness. This box acts as a guarantee: as long as that box remains entirely within the feasible region, every single engine that rolls off the line - despite manufacturing variations - is guaranteed to meet your vibration requirements.

Designing for real-world variation: The interactive user interface visualizes a 'bounding box' around the nominal design across a critical subset of high-impact input parameters. This ensures that even with the inevitable 10% variation in mount stiffness during mass production, the design remains safely within the feasible region. Each colored region in these 2D slices corresponds to a different performance requirement, allowing engineers to instantly see how manufacturing tolerances impact the interplay between multiple stringent targets.

As a final check, we ran a simulation at the design corresponding to the center of the sandbox: with errors ranging from only 0.10% to 0.61% for the different floor vibration metrics, we could confirm that Secondmind’s models, powered by Active Learning, were capable of providing highly accurate predictions, allowing decision-making with confidence.

The hidden interaction between Pitch and Yaw modes

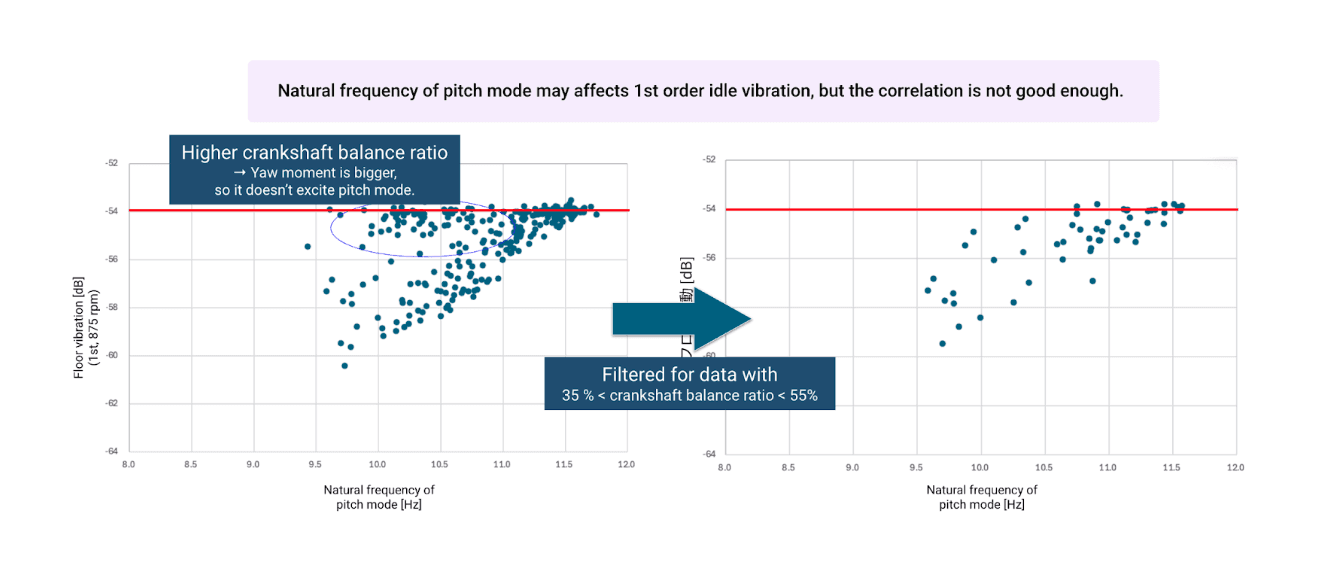

The visual exploration revealed a critical, previously unknown dynamic: the coupling of the Pitch and Yaw modes amplifies idle vibration. While the correlation between the natural frequency of the pitch mode and the 1st order idle vibration was initially not high enough, filtering the data to a narrow range of crankshaft balance ratios (35% < crankshaft balance ratio < 55%) showed that the Yaw mode acts as a hidden amplifier of floor vibration.

Initial analysis: Plotting pitch natural frequency vs. idle vibration showed a poor correlation.

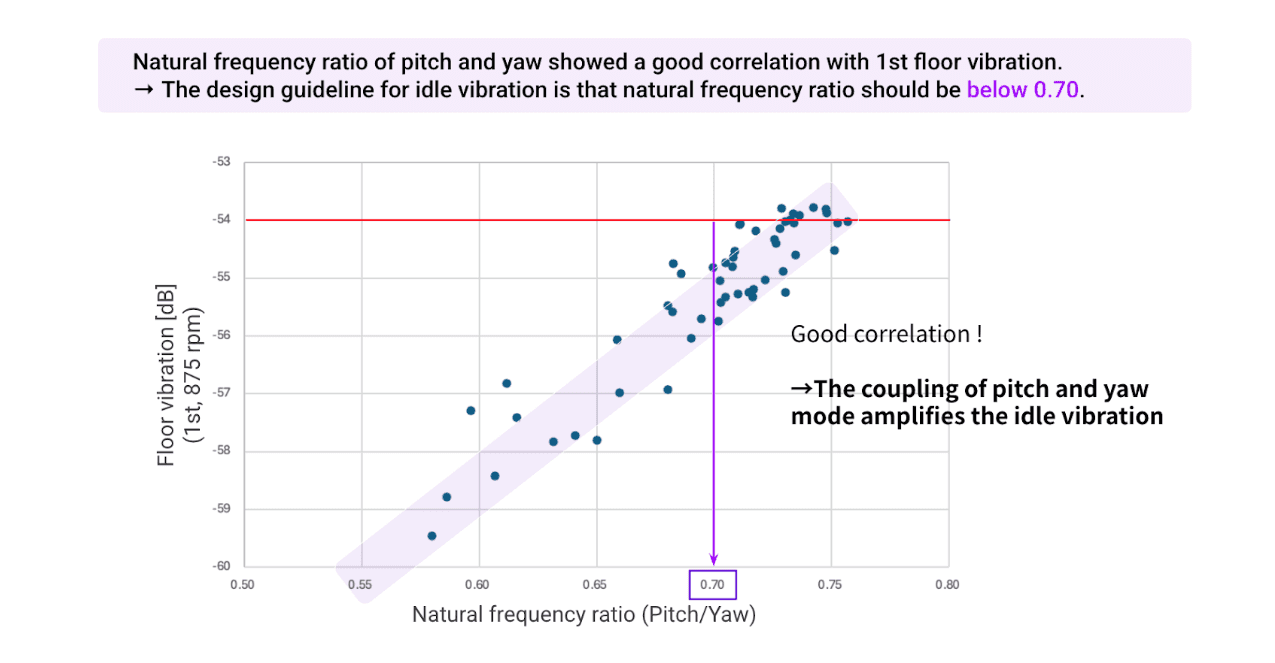

The key breakthrough came when we looked at the ratio of the natural frequencies for Pitch and Yaw modes. This ratio had a good correlation with the 1st floor vibration at 875 rpm.

The breakthrough: Plotting the pitch/yaw natural frequency ratio vs. idle vibration reveals a clear, predictive design guideline

This key insight allowed us to instantly codify new expertise for the design team, creating clear, predictive design guidelines for all future three-cylinder engine programs.

New predictive design guidelines

Based on the analysis, the team established two new, critical guidelines to satisfy the target for 1st idle vibration (875 rpm, A/C on) under the condition of a crankshaft balance ratio from 35% to 55%:

Engine pitch and yaw natural frequency ratio must be below 0.70.

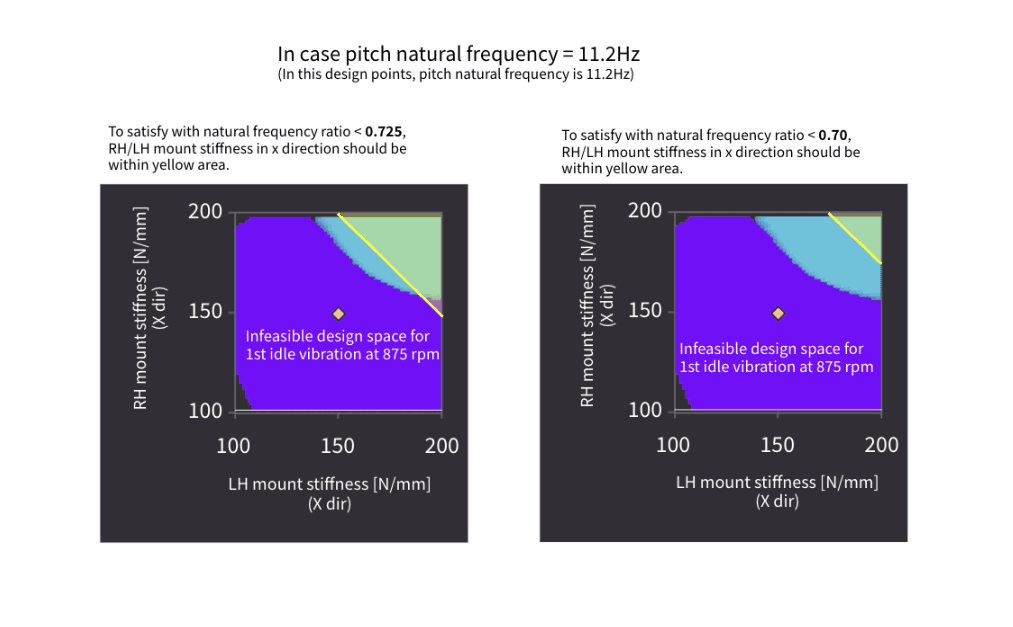

Engine pitch natural frequency must be below 11.2 Hz.

This knowledge enabled the team to visualize the feasible design space based on the new guideline. For example, to satisfy the natural frequency ratio <0.70, the RH/LH mount stiffness in the X-direction must be within the specified yellow area.

Visualization of feasible design space accounting for the design guideline of natural frequency ratio

By utilizing Secondmind for Design Space Exploration, we not only solved an immediate complex problem but also built robustness into the design from the start , significantly minimizing rework, and instantaneously upgraded the team's expertise for future projects. This shifts the engineering paradigm from reactive, point-based testing to proactive, robust design validation.

If you are currently facing similar complex engineering trade-offs and want to accelerate your development timeline while guaranteeing mass-production robustness, we’d love to hear from you. Reach out to our experts today to discuss how we can partner with your team to solve your most pressing technical challenges.